Reliable China N Type Aluminum Ground Solar Mounting for Diverse Terrain

November 01, 2025

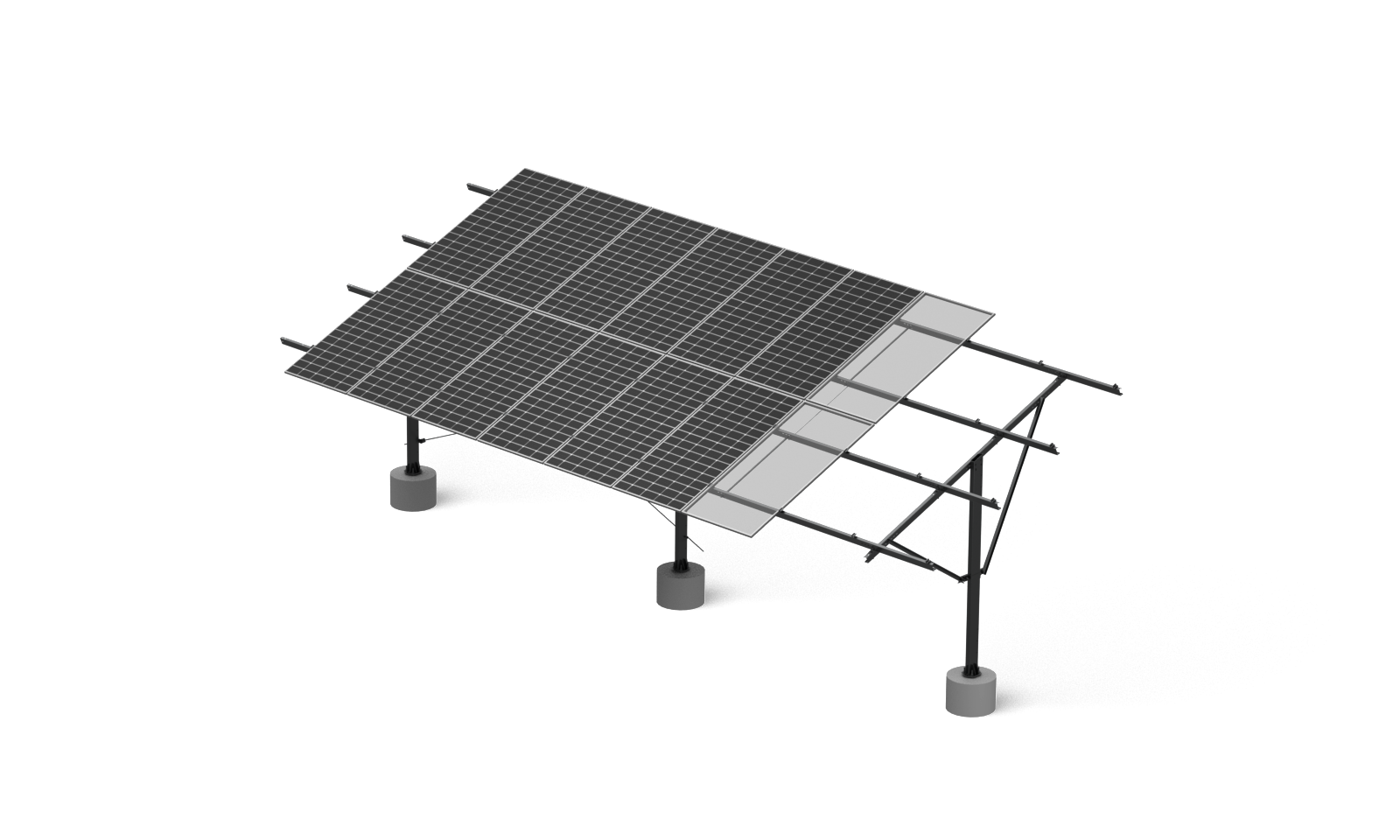

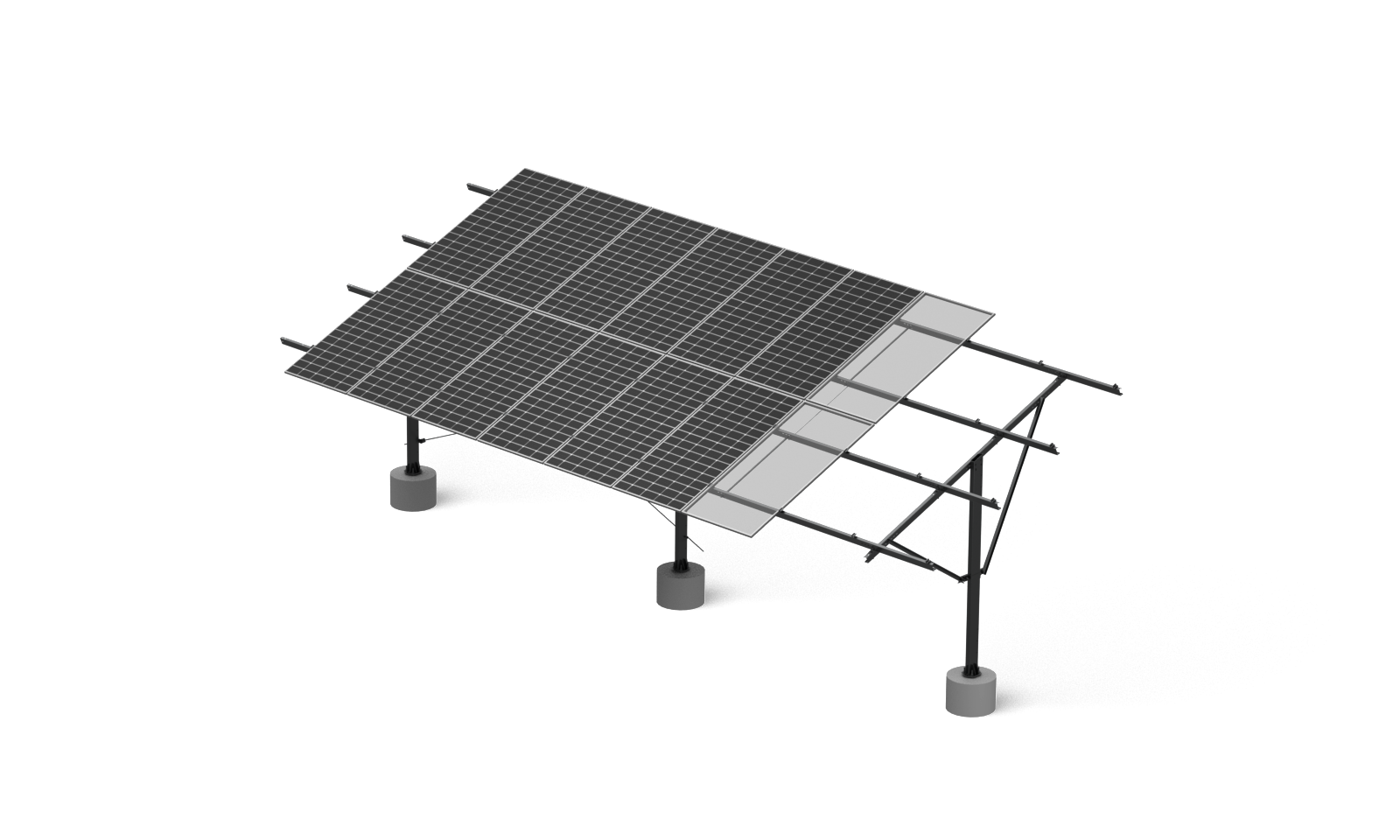

Flat or uneven terrain presents unique challenges for commercial solar projects. Businesses installing large-scale solar arrays must ensure that their mounting systems can accommodate foundation settlement, rooftop applications, and variable loads while maintaining long-term stability. Using China n type aluminum ground solar mounting provides practical solutions to these challenges, enabling smoother project execution and durable performance.

Concrete Foundations for Stability

Ground solar installations often require solid foundations to prevent shifting or settlement. Concrete foundation systems paired with China n type aluminum ground solar mounting offer excellent load-bearing capacity and maintain structural integrity even on uneven terrain. This combination is ideal for areas where soil variability or rooftop conditions might otherwise complicate installation. By providing a stable base, the mounts ensure that panels remain properly aligned and secure throughout their operational life.

Versatility Across Solar Racking Systems

Solar projects may involve a range of layouts, from flat land installations to rooftop arrays. The China n type aluminum ground solar mounting system is compatible with multiple ground mount solar racking designs, including elevated or open-frame configurations. Its flexibility allows businesses to use the same system across different project sites, reducing the need for multiple mounting solutions and simplifying logistics for large-scale solar deployments.

Pre-Fabricated Components for Quick Assembly

Installation efficiency is critical for commercial solar projects. Mounts with pre-fabricated components allow installation teams to assemble the structure quickly without extensive adjustments on-site. Using China n type aluminum ground solar mounting reduces labor costs, minimizes errors, and helps maintain consistent panel alignment, which is essential for optimal system performance.

Long-Term Reliability and Minimal Maintenance

Aluminum structures provide strong resistance to corrosion, making them suitable for both ground-mounted and rooftop solar systems. With a concrete foundation and high-quality aluminum mounts, businesses can ensure that their arrays maintain stability over time with minimal upkeep. This combination of strength and low maintenance reduces operational costs and ensures the solar project remains productive throughout its lifetime.

Conclusion

Project managers should prioritize foundation stability, terrain flexibility, and ease of installation while planning a ground-mounted solar installation. A dependable and adaptable approach is to combine concrete foundation systems with China n type aluminum ground solar mounting. This combination works for both level terrain and uneven soil, as well as rooftops. Companies can efficiently develop solar projects while maintaining long-term structural integrity and performance by prioritizing these practical criteria. Antaisolar offers mounting solutions that might help you achieve these realistic goals. Commercial solar installations can be confidently completed with our China n type aluminum ground solar mounting systems because of their long-lasting, stable, and adaptable design. This helps to minimize on-site obstacles.

Concrete Foundations for Stability

Ground solar installations often require solid foundations to prevent shifting or settlement. Concrete foundation systems paired with China n type aluminum ground solar mounting offer excellent load-bearing capacity and maintain structural integrity even on uneven terrain. This combination is ideal for areas where soil variability or rooftop conditions might otherwise complicate installation. By providing a stable base, the mounts ensure that panels remain properly aligned and secure throughout their operational life.

Versatility Across Solar Racking Systems

Solar projects may involve a range of layouts, from flat land installations to rooftop arrays. The China n type aluminum ground solar mounting system is compatible with multiple ground mount solar racking designs, including elevated or open-frame configurations. Its flexibility allows businesses to use the same system across different project sites, reducing the need for multiple mounting solutions and simplifying logistics for large-scale solar deployments.

Pre-Fabricated Components for Quick Assembly

Installation efficiency is critical for commercial solar projects. Mounts with pre-fabricated components allow installation teams to assemble the structure quickly without extensive adjustments on-site. Using China n type aluminum ground solar mounting reduces labor costs, minimizes errors, and helps maintain consistent panel alignment, which is essential for optimal system performance.

Long-Term Reliability and Minimal Maintenance

Aluminum structures provide strong resistance to corrosion, making them suitable for both ground-mounted and rooftop solar systems. With a concrete foundation and high-quality aluminum mounts, businesses can ensure that their arrays maintain stability over time with minimal upkeep. This combination of strength and low maintenance reduces operational costs and ensures the solar project remains productive throughout its lifetime.

Conclusion

Project managers should prioritize foundation stability, terrain flexibility, and ease of installation while planning a ground-mounted solar installation. A dependable and adaptable approach is to combine concrete foundation systems with China n type aluminum ground solar mounting. This combination works for both level terrain and uneven soil, as well as rooftops. Companies can efficiently develop solar projects while maintaining long-term structural integrity and performance by prioritizing these practical criteria. Antaisolar offers mounting solutions that might help you achieve these realistic goals. Commercial solar installations can be confidently completed with our China n type aluminum ground solar mounting systems because of their long-lasting, stable, and adaptable design. This helps to minimize on-site obstacles.

end